Your Needs our Goal

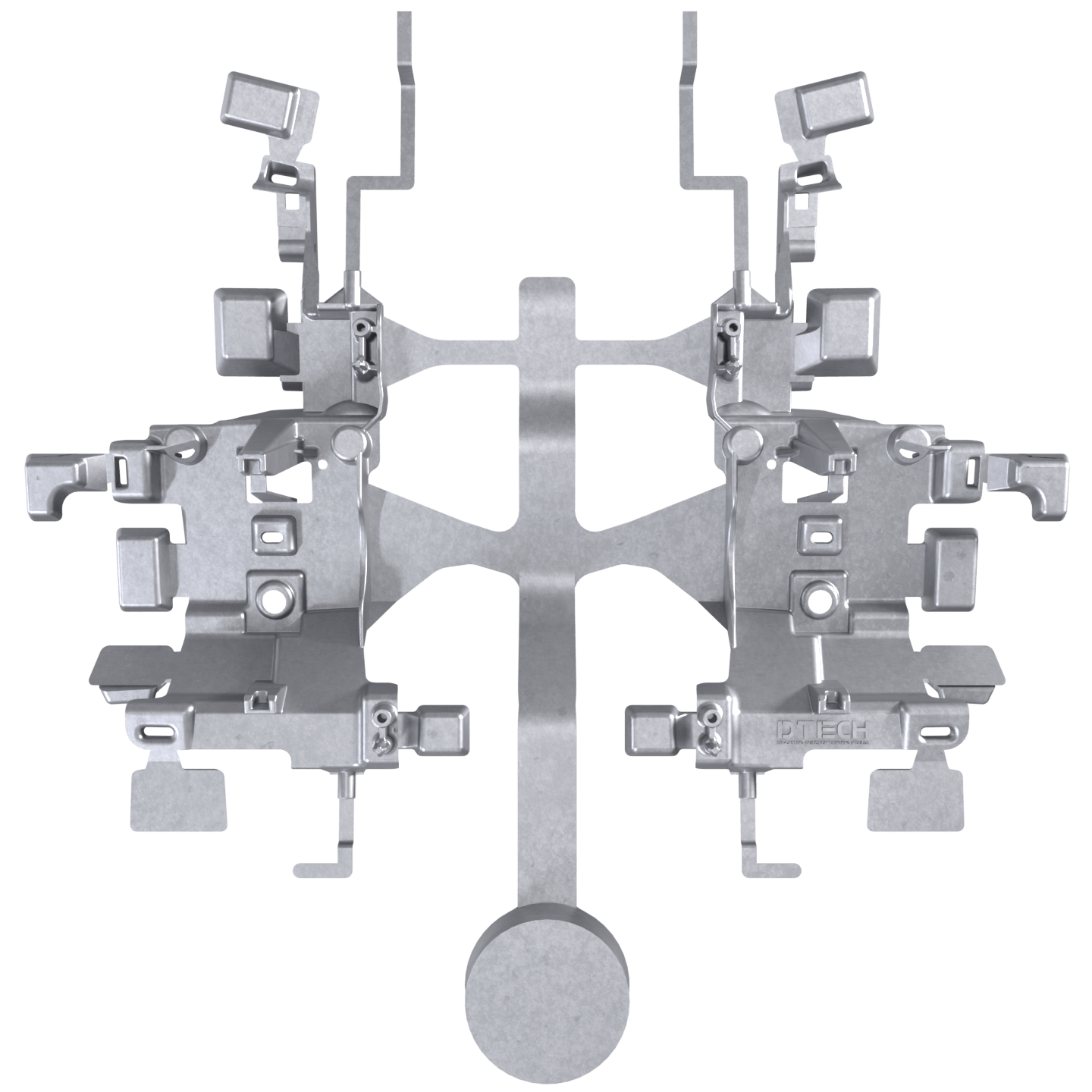

Die casting • Injection • Trimming moulds

Why DTECH

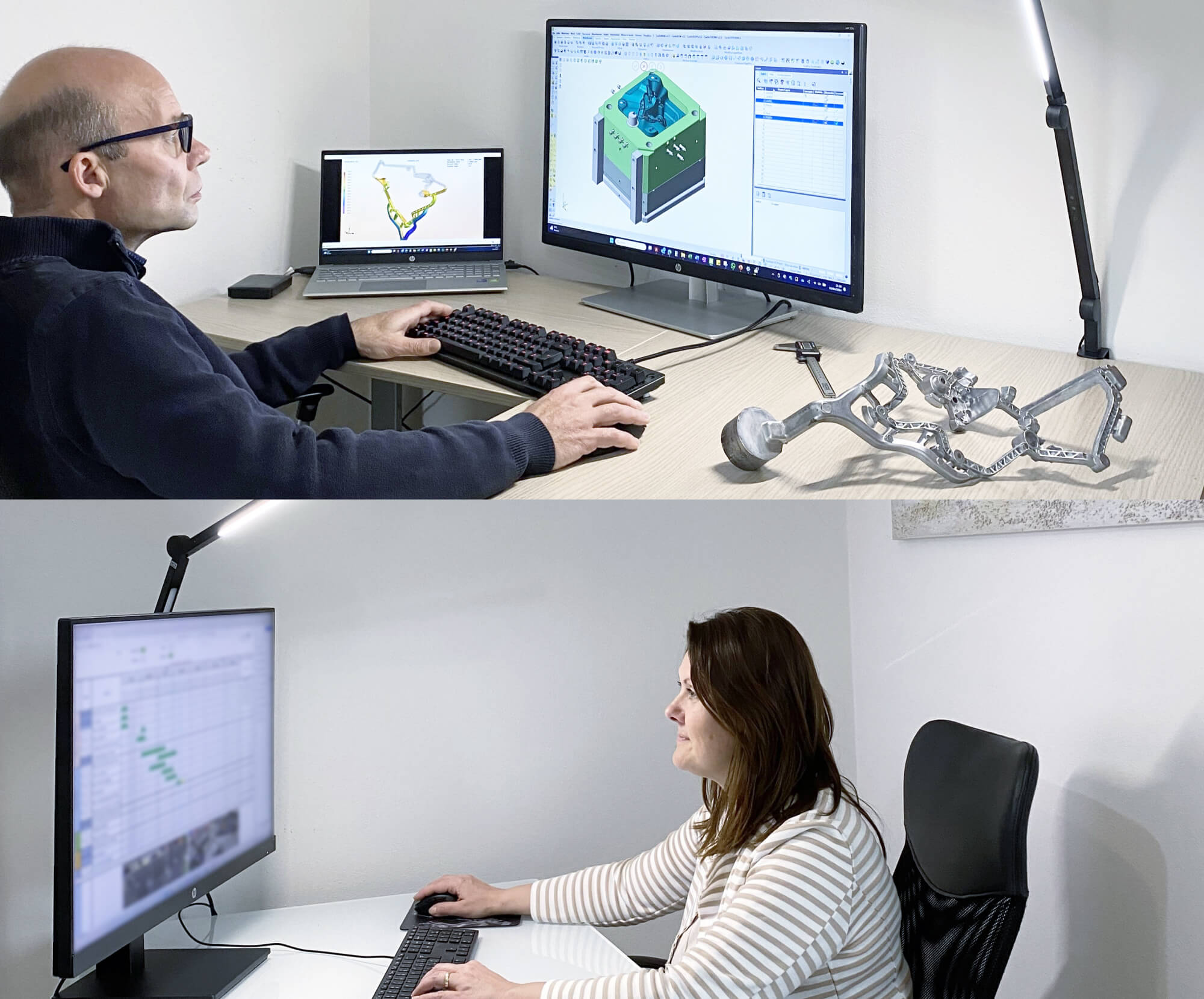

Understanding

Understanding customer needs is critical to providing tailored solutions. Our attention to detail and listening skills set us apart, ensuring that every customer feels supported at every stage of the process.

Thorough knowledge of the industry allows us to achieve results that meet expectations.

Proactivity

The cornerstone of our corporate philosophy is to maintain a high standard of service, anticipating the needs of our customers and acting promptly to meet them.

This constant commitment guarantees a reliable and high quality service.

Service and warranty

We are committed to providing a complete service to our customers, offering solutions to your needs and constant support throughout the process and life of the mould.

We guarantee the use of certified and high quality materials.

Main areas of application

DTECH, is specialized in the manufacture of moulds for the production of structural, mechanical and aesthetic components for various sectors, including