Custom services and solutions

from design to mould production

Consulting

We offer an integrated and specialized approach to meet the needs of our customers in the field of mould making. Thanks to our extensive experience and technical expertise, we provide personalized advice, from the evaluation of project specifications to the delivery of the finished product. Through a professional and customer-oriented approach, we are committed to ensuring innovative, efficient and high-quality solutions.

Feasibility study

The feasibility study aims to assess the feasibility and convenience of a production project. Through an in-depth analysis of customer requirements, product specifications, and technical and financial constraints, our expert team carefully assesses available options and identifies the most beneficial solutions.

This process includes assessing design complexity, finding appropriate materials, analysing costs and production times, and assessing potential risks.

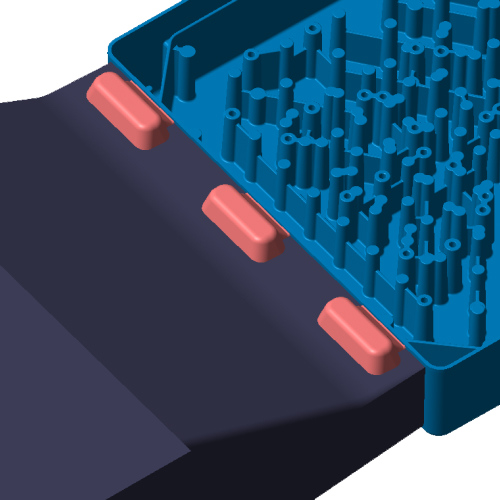

Prototyping

The construction of soft tools represents an innovative and highly effective offer in the field of the production of prototype parts with the same characteristics of the final production process. Using advanced manufacturing techniques, we can create prototypes using temporary tools and materials.

This methodology allows us to test and validate component design efficiently, reducing development time and optimizing the production process and achieving high-quality prototypes quickly and cost-effectively. Mechanical processing and finishing treatments complete the service.

Co-design

Co-design is a collaborative and synergistic approach. In collaboration with our customers, we develop innovative and optimized solutions that meet the specific requirements of the project. Through brainstorming sessions, in-depth analysis and iterative prototyping, the co-design process allows to maximize efficiency, reduce development time and ensure the highest quality of the final product.

Thanks to our experience and industry expertise, we offer a co-design service that promotes creativity, collaboration and shared success.

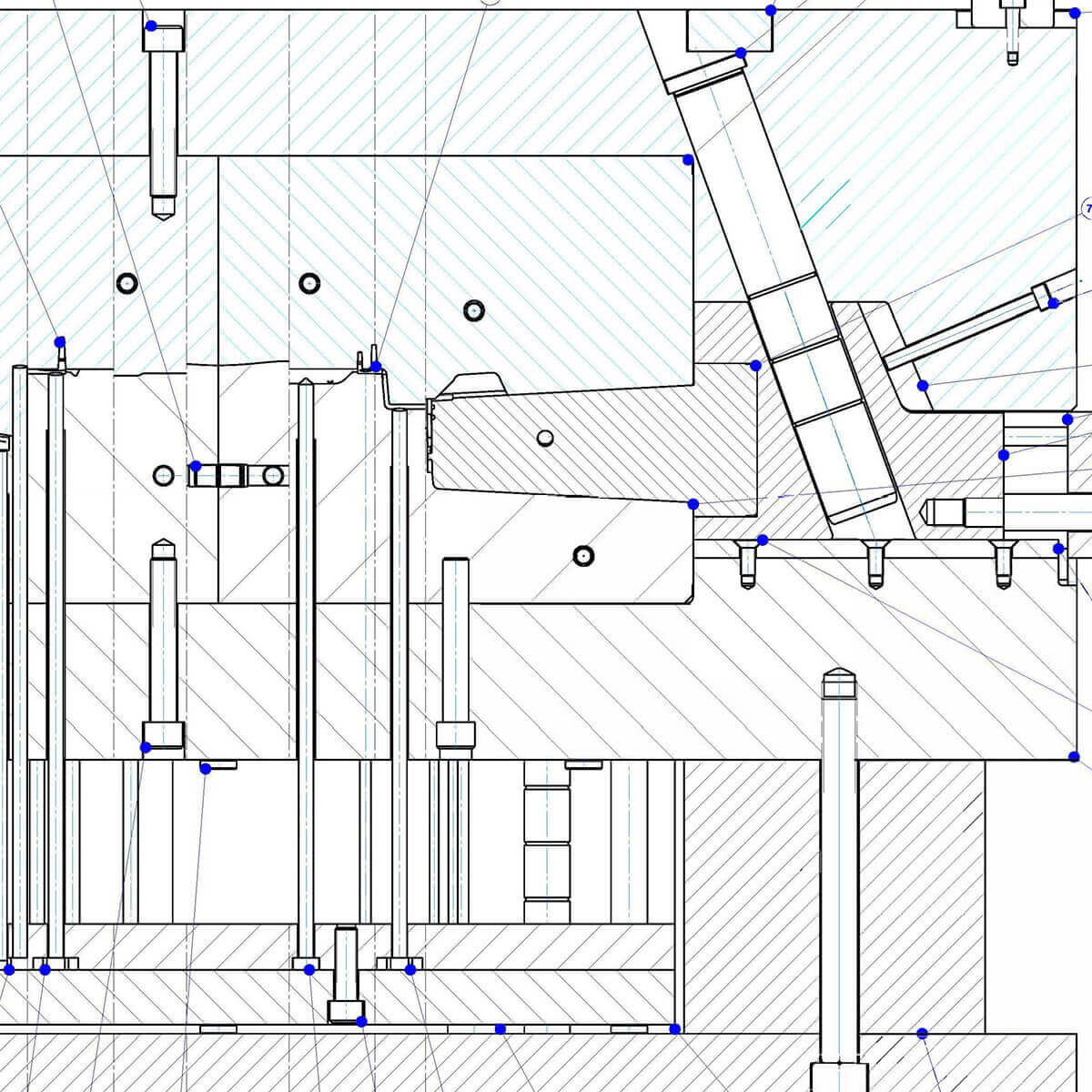

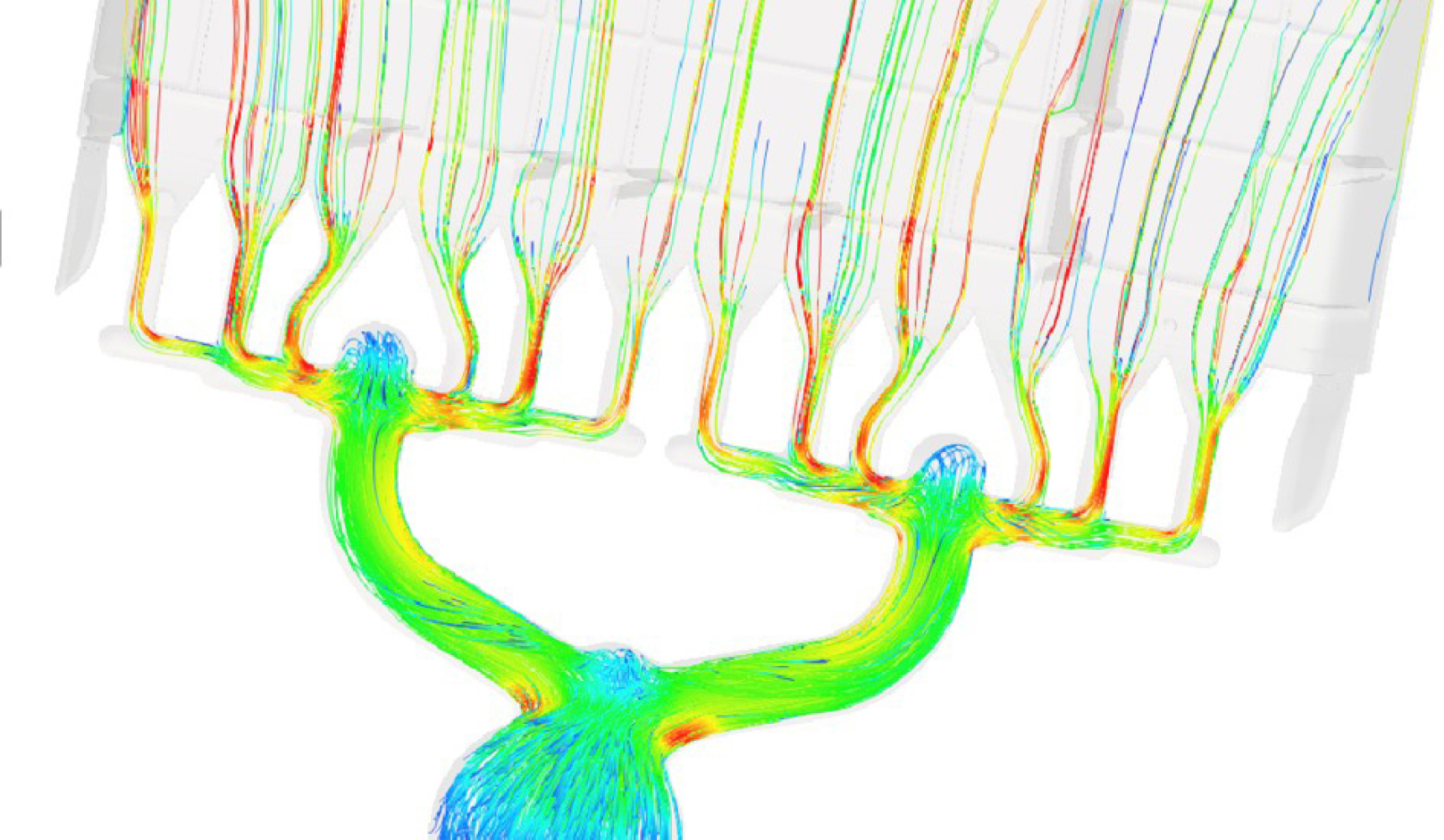

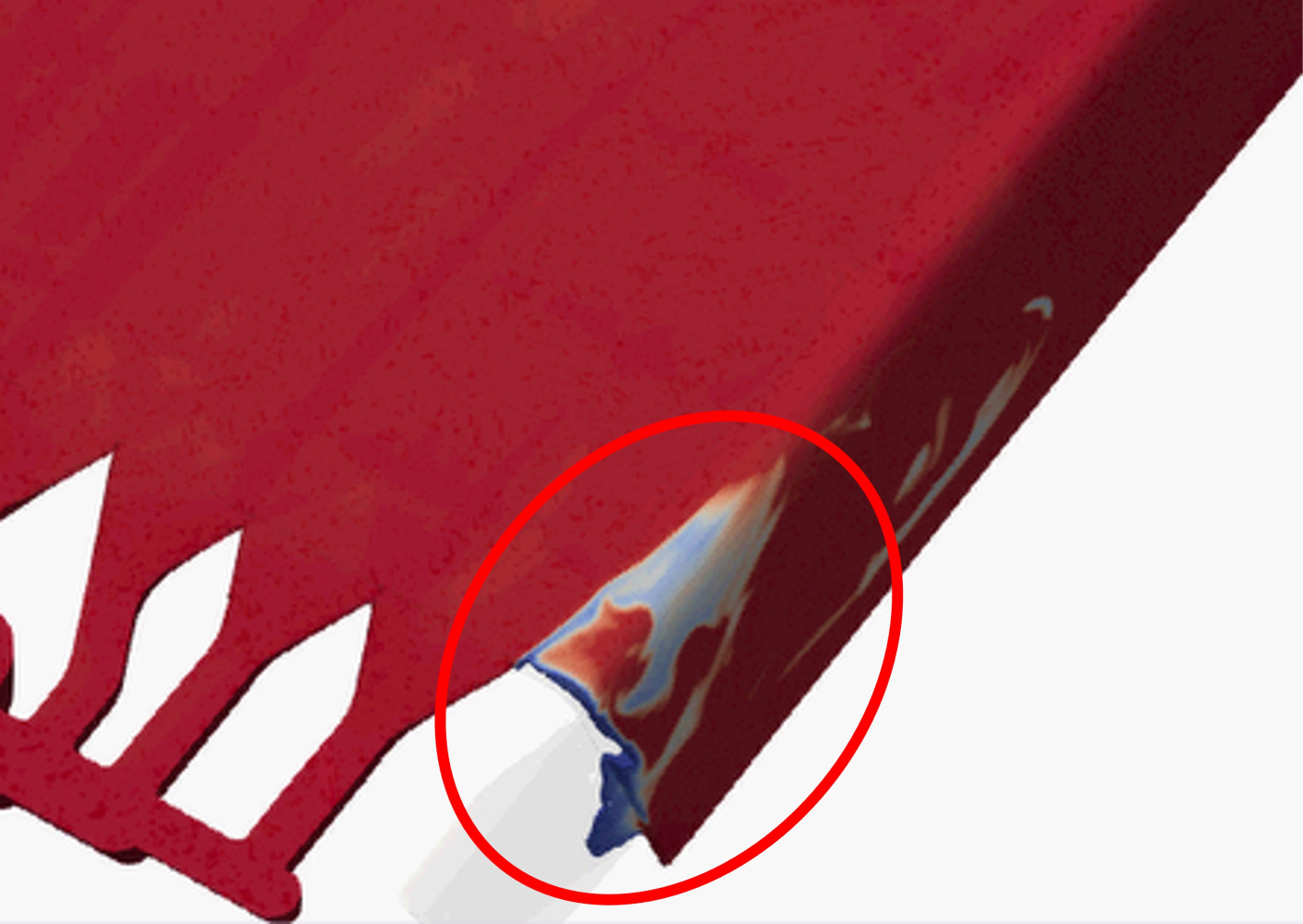

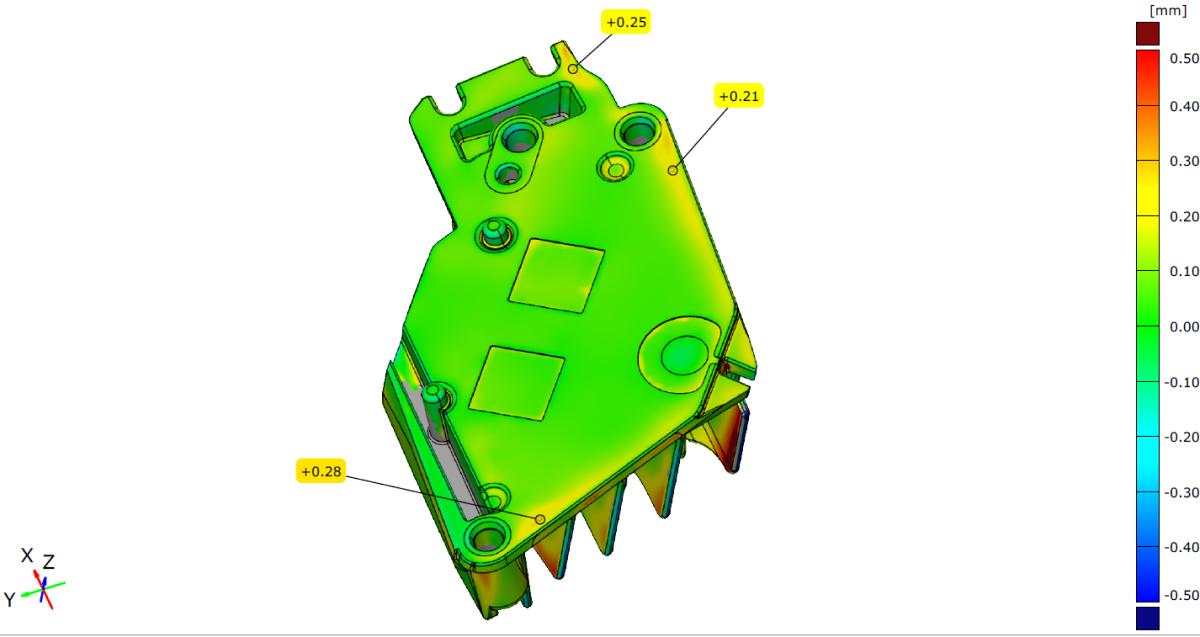

Mould flow and deformation simulation

Mould flow uses numerical analysis software to conduct detailed simulations of the die casting and plastic molding process. This includes mould filling modeling, metal solidification analysis, temperature distribution evaluation, and prediction of defect formation and possible part deformation.

This approach allows you to identify and solve potential production issues, optimize mould design and process parameters, and ensure the highest quality and compliance of the finished product.

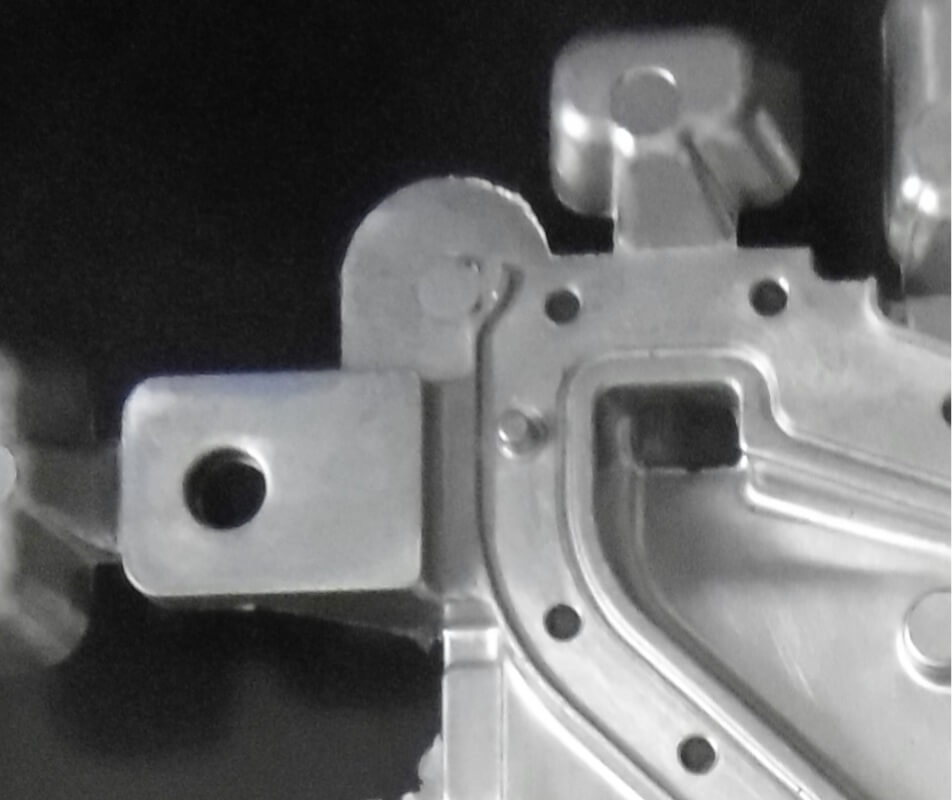

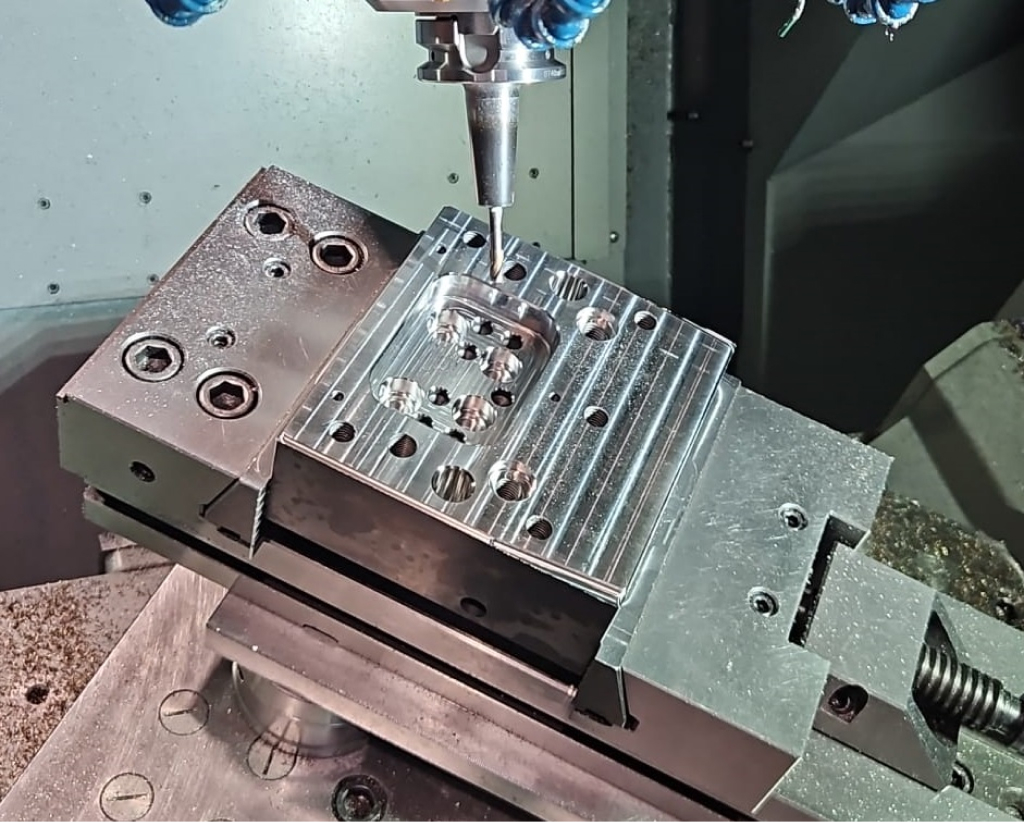

Design and manufacturing of moulds

The heart of DTECH is the design and manufacture of moulds. The integrated approach includes customer specification assessment, design optimization, casting and deformation simulation, mould construction using certified materials and advanced machining techniques.

Rigorous job progress and dimensional and functional controls ensure maximum precision, quality and reliability at every stage of the process, to provide our customers with mould solutions that meet the highest standards of performance and durability.

GANTT progress

We use this advanced planning methodology to provide a clear and detailed view of the activities and timing involved in the mould design and construction process.

Through the creation and regular updating of the Gantt diagram, we effectively coordinate human and material resources, identify and resolve potential planning conflicts, and continuously monitor the progress of the project.

This approach allows us to optimize the planning and control of activities, ensuring timely delivery.

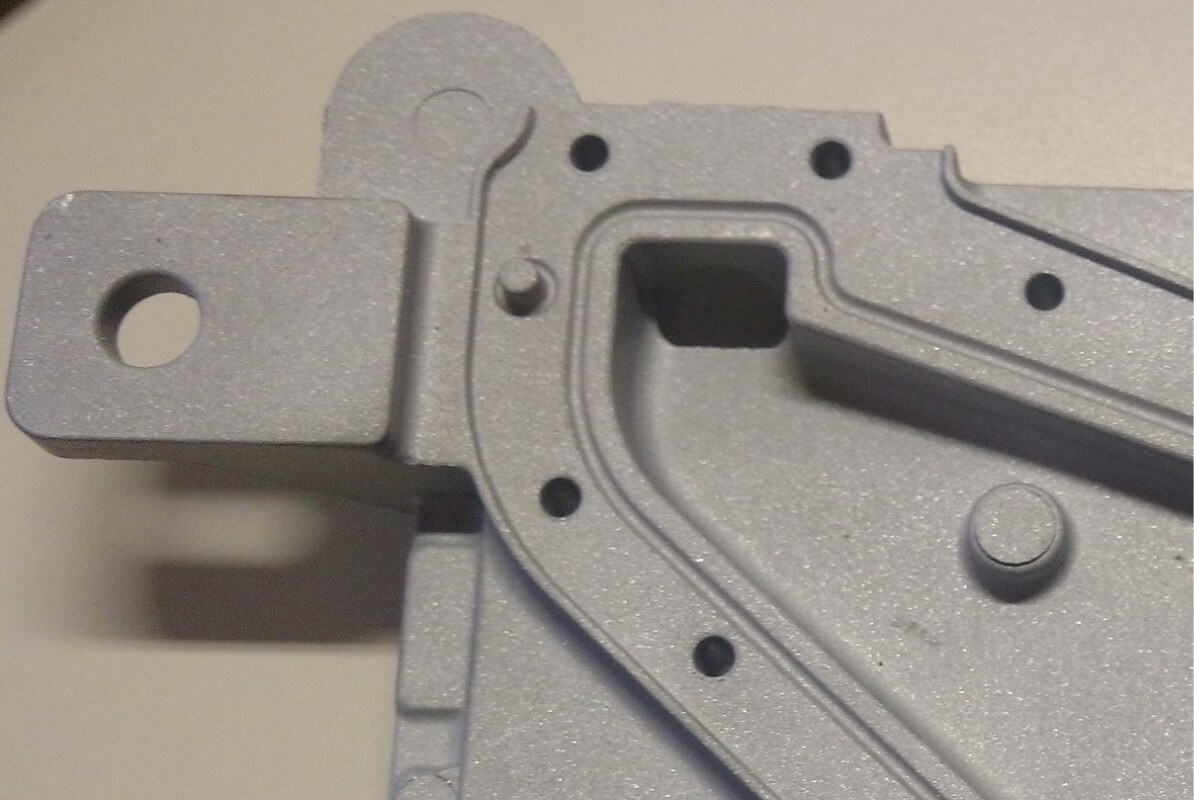

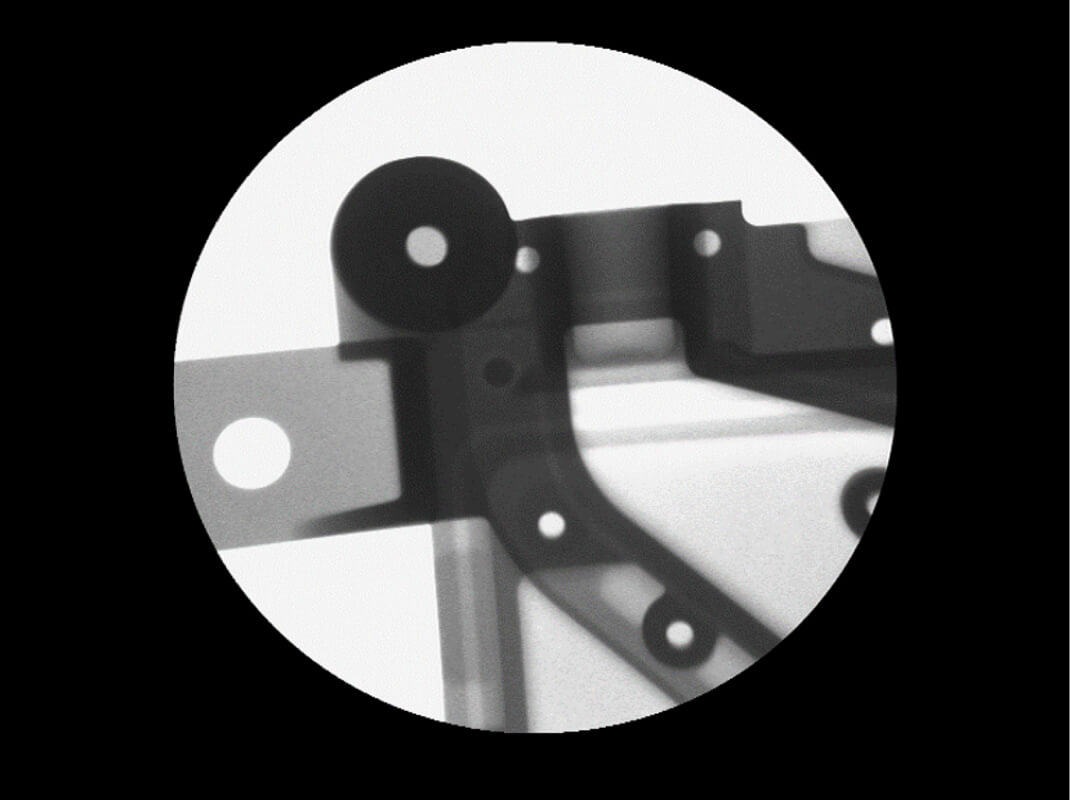

Sampling

We offer sampling services that include the production of initial stamping samples for process validation. These samples undergo rigorous quality control, including detailed dimensional measurements and in-depth analysis to ensure compliance with the required specifications.

We use advanced technologies and precision instrumentation to perform checks, ensuring that each sample meets production standards.

Service

Post-construction assistance and maintenance of the moulds is the support for the entire life of the moulds that guarantees the maintenance of the optimal performance and the maximum operating efficiency.

This service includes timely troubleshooting, mould repair and optimization, and preventive management of scheduled maintenance.